Ông Chan

Để lại tin nhắn

Ông Chan

Để lại tin nhắnThe advantages of 3D printing are well documented. The technology allows products to be created at the location where they are needed. It helps deal with efficiency problems, making supply chains move forward smoothly. This can have a massive impact in reducing the resources and time needed to manufacture products.

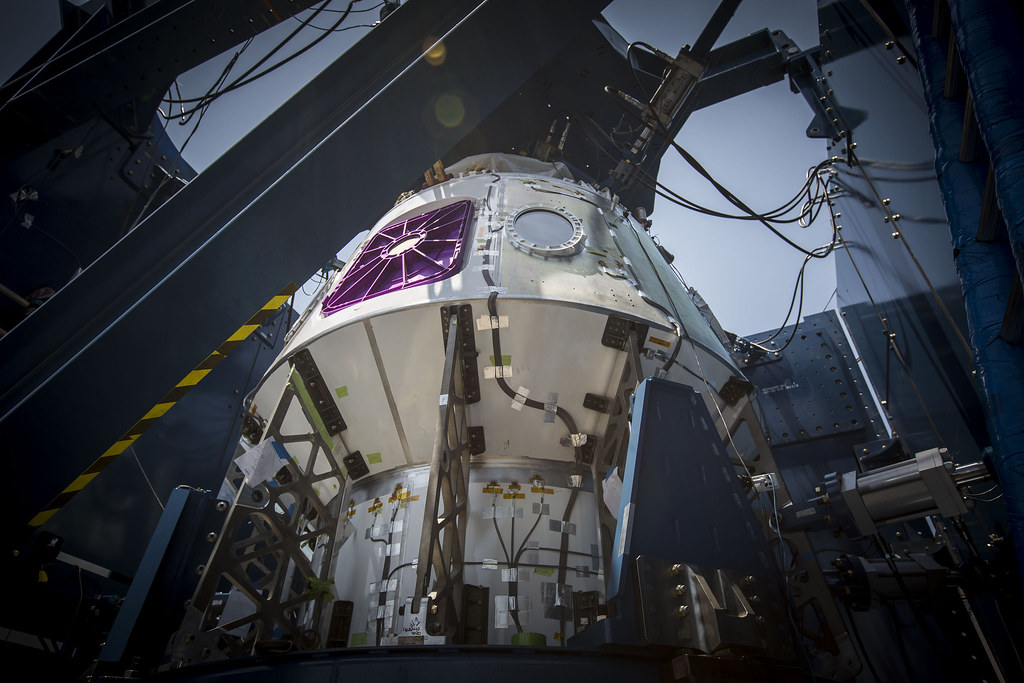

Rocket companies have used 3D printing, formally known as additive manufacturing, for the better part of the last decade, beginning with SpaceX`s 2013 development of a 3D printed part of the SuperDraco rocket engine.

This article follows the history of the use of 3D printing in new space companies. Towards the end of the article, we will also look at another advanced manufacturing technique used by these companies: high-pressure die casting.

Let`s start with a reminder of what 3D printing technology involves. There is no better place to look for the definition of 3D printing than from the masters of 3D printing, Autodesk.

Autodesk defines 3D printing as [a process by which physical objects are created by depositing materials in layers based on a digital model." The same source adds that [3D printing technology can be used to create everything from prototypes and simple parts to highly technical final products such as airplane parts -, eco-friendly buildings, life-saving medical implants and even artificial organs using layers of human cells."

Autodesk identifies three primary methods employed when manufacturing items using 3D:

Fused filament fabrication (FFF): Mainly in manufacturing consumer products, this method heats and extrudes plastic material in layers that form the required product. It`s also called fused deposition modeling (FDM).

Stereolithography (SLA): Uses UV light to harden or cure raisings, one layer after another.

Selective laser sintering (SLS): Fuses powdered materials using lasers, layer by layer.

The additive manufacturing software provider, AMFG, provides some insights into the impact of 3D manufacturing in the space travel field. The company notes that the [spacecraft manufacturers are faced with the challenge of accelerating rocket development and production, while also reducing costs and increasing efficiency."

AMFG says that the traditional rocket manufacturing process involves several prototyping cycles and phases of production, rendering the process expensive and time-consuming. The same source says that the 3D manufacturing process can reduce the manufacturing time for parts from a traditional 14-week period to only a few weeks, giving manufacturers significant savings on time and costs.

3D manufacturing also ensures the precision of parts, which is a challenging task when using traditional manufacturing methods.

Elon Musk established SpaceX in 2002. His mission was to reduce the cost of traveling to space so that humans could eventually colonize Mars. According to SpaceX, this would be achieved through the use of [fully reusable launch vehicles that will be the most powerful ever built, capable of carrying humans to Mars and other destinations in the solar system."

On September 5, 2013, Musk announced via a tweet that [SpaceX SuperDraco inconel rocket chamber w regen cooling jacket emerges from EOS 3D metal printer."

The source of news on space exploration, innovation, and astronomy, Space.com reports that [SpaceX sent its first 3D-printed part into space early this year [2014]." The same source adds that [The part, a rocket engine main oxidizer valve, flew aboard SpaceX`s Jan. 6 launch of a Falcon 9 rocket carrying the commercial Thaicom 6 telecommunications satellite to orbit."

The practicality of using 3D printing to make rocket parts was validated by the fact that the valve worked as required under strenuous conditions, including under extremely low temperatures.

SpaceX is also using 3D printing technology to produce other accessories such as helmets. According to 3Dnatives.com, [Each helmet features a visor, valves, locks, and microphones."

Tuyên bố về quyền riêng tư: quyền riêng tư của bạn rất quan trọng với chúng tôi. Công ty của chúng tôi hứa sẽ không tiết lộ thông tin cá nhân của bạn cho bất kỳ công ty bên ngoài nào mà không có sự cho phép rõ ràng của bạn.